GEA: Oil and gas geothermal co-production could extend possibilities

The U.S. Geothermal Energy Association assumes that a lot of heated waste-water from oil and gas production could be used for geothermal power production with up to 1MW of potential per well, so a recent article by the association in Renewable Energy World.

The U.S. Geothermal Energy Association assumes that a lot of heated waste-water from oil and gas production could be used for geothermal power production with up to 1MW of potential per well, so a recent article by the association in Renewable Energy World.

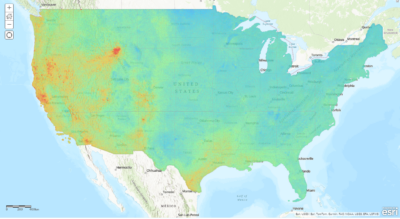

Generally oil companies are receptive to the idea of turning a liability into an asset and expanding the economic potential of their oil wells. And why not, since in the past, wastewater from oilfield production processes was viewed as a nuisance byproduct that needed to be disposed of. But new research has shown that much of the 25 billion barrels of this geothermally heated “wastewater” produced at oil wells each year in the U.S. is hot enough to produce electricity. It is estimated that many of the wells might have clean energy capacities of up to 1 MW.

Oil and Gas Coproduction in the US

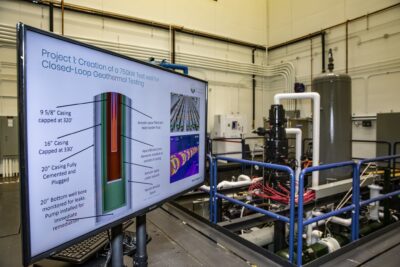

In 2008, the DOE developed the first low-temperature geothermal unit in an oil field at the Rocky Mountain Oilfield Testing Center (RMOTC) in Wyoming. The well is producing energy and has a capacity of approximately 217 kW. RMOTC continues to test power units produced by Ormat Technologies and UTC/Pratt and Whitney Power Systems at the center and more than 30 oil firms have visited the center to learn about coproduction technology. The technology is also being implemented in Nevada, Mississippi, Louisiana, North Dakota and Texas.

In Nevada, Florida Canyon Mining Inc. is using the 220°F groundwater in a coproduction project that usesElectraTherm’s 50-kW waste heat generators, aka “Green Machines” to generate electricity.

Energy can be harnessed at working oilfields and used to power them without interrupting their operation. A Gulf Coast Green Energy (GCGE) coproduction project at the Denbury oilfields in Laurel, Mississippi, is using this technique again with ElectraTherm Green Machines. It replaced Denbury’s electric submersible pump and cut electricity costs by a third. GCGE has a second 50-kW geothermal natural gas coproduction project in Louisiana.

University of North Dakota was awarded $1.7 million through the DOE’s Geothermal Technologies Program to install a geothermal Organic Rankine Cycle (ORC) system at another oilfield operated by Denbury. For two years the plant will be used to develop engineering and economic models for geothermal ORC energy production. The technology could be used throughout the Williston Basin.

Liberty County Pilot Project

Texas is oil country, and the 4000+ dormant oil and gas wells speckled across the landscape provide a new, or perhaps recycled, frontier in geothermal energy production. To tap some of that energy, Universal GeoPowerCEO and petroleum geologist George Alcorn Jr. and his partner, Chris Luchini, a PhD physicist will use the $1.5 million in federal stimulus funds that they were awarded to bring geothermal energy to Liberty County, Texas. The company said that to prepare its DOE application, it worked with Southern Methodist University. The university has performed extensive research on coproduction and has found that it is applicable to an estimated 37,500 oil and gas wells in the Gulf Coast region.

Universal GeoPower’s pilot project is expected to be one of many that will recomplete the wells to produce low temperature, geopressured brine water. The brine will run through a commercial off-the-shelf turbo expander and an ORC binary generator.

Alcorn spoke recently at GEA’s global geothermal meeting in Washington, DC, offering a snapshot of the economic benefits of the process. “The lead-time to revenue generation is about 6 months, whereas traditional geothermal can take up to five years,” he said. “The wells already have known geothermal potential, and capital costs are dramatically reduced.”

Additionally, Alcorn noted, units are installed at existing oil wells, eliminating the need for investment in drilling, new roads or transmission lines.

If coproduction can be considered the “new kid on the block” it is quickly becoming one that many believe will leave a big impression. Coproduction is expected to be a hot topic at GEA’s upcoming Utilities, Co-Ops and Public Power Workshop on July 22 in Las Vegas.

The support of oil and gas geothermal coproduction is just part of DOE’s interest in innovative geothermal technologies. A $20 million funding opportunity announced in May for research, development and demonstration of geothermal technologies included, along with fluids recovered from oil and gas wells, other non-conventional geothermal technologies such as low-temperature fluids (up to 300°F) and highly pressurized geothermal fluids. The Sweetwater Lake Geopressured project in Louisiana has already received ARRA funding.

If the work being undertaken by ElectraTherm, Gulf Coast Green Energy, Universal GeoPower and others is successful, a new era of geothermal power could be launched. A 1-MW power generator is small in conventional geothermal terms, but the potential for hundreds of these to be brought online within a short period of time is promising. From the Gulf Coast to the Dakotas, geothermal coproduction could bring clean energy and new jobs from old oilfields.”

Source: Renewable Energy World