Good backgrounder on Turboden and ORC, interview with Joseph Bonafin

In a recent interview, Joseph Bonafin, Sales and Business Development Manager at Italian ORC provider Turboden, he provides a good background on the company and ORC technology.

In a recent interview with Joseph Bonafin, Sales and Business Development Manager at Italian ORC supplier Turboden, he provided some interesting background on the company and ORC technology

What is the background of Turboden as a company?

Turboden is a pioneer of Organic Rankine Cycle (Binary) power plant and turbine technology, with more than 35 years’ experience in this field of application. Turboden started as first mover in the research of ORC in the Sixties, and grew up as a solid and reputable company in the market. As the “Binary arm” of Mitsubishi Heavy Industries, geothermal world leader for number of plants installed and 51% quota-holder, Turboden has created the biomass and waste heat recovery ORC markets, and has experience with geothermal since the Eighties. Totally there are about half Gigawatt of Turboden’s Binary plants all over the world, with more than 7 million cumulative operation hours.

Today, Turboden is one of the two companies in the Binary market that can demonstrate proven field experience with both turbine and plant design, the only one with successful experience with 9 different ORC working fluids. Turboden has a special mandate from Mitsubishi to target larger size projects, and keep on satisfying its customers (meaningful is that many of its customers are repetitive) by providing the highest performances and reliable and dependable systems.

What essentially is ORC?

The Organic Rankine Cycle’s (ORC) principle is based on a turbogenerator (working on a closed-loop) as a traditional steam turbine, to transform thermal energy into mechanical energy and finally into electric energy through an electrical generator. Instead of water steam, the ORC system vaporizes a suitable and safe organic fluid, characterized by a molecular mass higher than water, which leads to a slow rotation of the turbine (1,500 to 3,000 rpm) and low nominal pressure. Organic Rankine Cycle offers many advantages, such as high turbine and thermodynamic cycle efficiency, turbine’s low mechanical stress, absence of moisture during the vapor expansion thus avoiding erosion of the metallic parts and blades, simple start-up procedures, automatic and continuous operation, simple maintenance procedure, no operator attendance required, long life of the plant (> 20 years), no need to demineralize water.

Thanks to these advantages, at present more than 300 Turboden plants have been delivered worldwide.

What is Turboden position with respect to the geothermal renewable energy and emissions?

Turboden has always had as a mission the production of electricity by means of green technology, with no harmful emissions in the atmosphere. Geothermal energy is an environmentally friendly and renewable source of energy. It is well positioned to play an important role in mitigating global climate change, increasing national energy security, and making the economy more competitive.

Some types of conventional geothermal power plants in Europe (Italy, Iceland, Turkey) release gases into the atmosphere during the power conversion process due to the natural presence of dissolved gases (mainly Carbon dioxide). However, it should be highlighted that the processes of natural CO2 generation happen independently of geothermal exploitation.

During the industrial exploitation of a geothermal field, the natural emissions are concentrated in the plants, but the surface manifestations, including soil degassing, are strongly reduced.

Modern types of medium and low enthalpy geothermal plants (binary systems, EGS) produce near-zero emissions.

In particular, Turboden is very proud of its geothermal plants in Germany, working with performances higher than the guaranteed ones and using a real zero emissions technology. In fact, the geothermal resource is kept under pressure by a geothermal down-hole pump (Electrical Submersible Pump, ESP) and then re-injected in the same reservoir, thus avoiding to release in the air any quantity of Non-Condensable Gas (NCG, mainly CO2) or other pollutants.

Which are the advantages of Turboden technology?

As a first design step, Turboden always selects the best ORC fluid in terms of maximum NET output producible (high flexibility in the working fluid selection is one of Turboden’s competitive advantage). Furthermore, criteria of optimization are considered and sensitivity analysis is performed for every customer.

Turboden’s turbines are axial multi-stage 1,500 rpm, with isentropic efficiency close to 90%. Easy and quick (< 1 day) maintenance will be ensured by Turboden’s patented fluid-sealing system (in case of substitution of bearings and seals).

As an after-sales service, Turboden offers to its customers proven 5+ years spares & guarantee packages.

Turboden monitors its installation together with the 260 plants fleet from remote, and give day-by-day assistance and guidance to operators, who will be fully trained by Turboden’s staff. In case of quick unplanned intervention needed, Turboden is organized with local services and technical workshops with specialized staff.

These are some advantages that explain why projects with selected Turboden’s technology maximize the value and the guarantee of the Return Of Investment (ROI).

What is Turboden’s turbine technology?

Turboden’s turbines are axial type, which is the most proven configuration in the power industry.

Internal standard design procedures include specification for the construction materials, dimensional inspections, pressure tests, balance grade and respect common practice for expansion turbines of this size and application in power generation plants.

All the parts are subject to dimensional inspection before being assembled. Turbine casing is pressure tested. The turbine rotor assembly is dynamically balanced according to ISO 1940 G1. The turbine operates below the first critical speed and it is designed to withstand an overspeed of 30% above the operating speed. The turbine is equipped with a double mechanical seal between the process side end the external side. Mechanical seal and hydraulic circuits are pressure tested against leaks during the assembly process. Instruments are selected according to specific market regulations.

All Turboden’s turbines in operation have vibration values within few decimals of mm/s: this means high dependability and long life.

The casing, the shaft, the bearing, and lube system are standardized, while the blading and the number of stages are tailored case by case

Turboden designs and manufactures its own axial turbines with the highest technological and quality tests provided by Mitsubishi, with cutting-edge performances and provides, according to the specific conditions, the optimum number of turbine stages in order to maximize the energy production all over the operative range (seasonal ambient temperature variation). As of today, many 3 – 4 stages turbines are in operation and recently a 5 stage overhung turbine has been designed and assembled.

New optimized axial turbines, multi-stage, can have efficiencies much higher than in the past. For an application discussed in a paper presented by another binary turbine supplier at the World Geothermal Congress 2015, an “old-fashioned” 2 stages turbine has been presented with an efficiency of 80% versus the 84.5% of a radial turbine. Turboden has recalculated the expected efficiency of a modern axial turbine in the same conditions: 82.4 for 2 stage, 85.6 for 3 stage and 85.7 for a 4 stage axial turbine.

This demonstrates that a statement like «radial centrifugal turbine are intrinsically more efficient than other turbines configurations» is basically mistaken.

Turboden can now offer a single shaft 20 MW axial turbine at 1,500 rpm. The output has been carefully increased step-by-step in a 35 years’ growth. Turboden holds more than 30 patents in turbine design and a field experience of more than 7 million hours of operation.

Which are the advantages that Turboden and Mitsubishi can combine with their technology?

Geothermal fluids in certain locations contain high proportions of non-condensable gases. At locations where the geothermal fluid is sufficiently energetic, flash cycles are often preferred. However, the cost and parasitic power consumption of non-condensable gas (NCG) removal systems can be considerable. Since binary plants do not require extensive NCG removal equipment when harnessing such a resource, in such cases a combined cycle (MHPS steam turbine with bottoming Turboden’s binary unit) can be the best solution in terms of utilization of the resource and reduction of the cost of the equipment installed.

Turboden and Mitsubishi are able and available to study each different case and lead the customer to the optimal solution.

Which are the most important geothermal markets for Turboden?

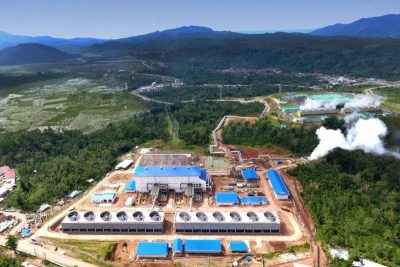

Geothermal potential is everywhere. Turboden is globally present and is expanding its operations from Europe to Middle East (Turkey) and Far East (Philippines and Japan). Turboden is also carefully looking at emerging markets like New Zealand, Africa and Americas.

Turkey, in particular, is one of the richest countries for geothermal potential, and has achieved a significant development in geothermal electricity production and direct uses in the last years. To continue this growth, a challenging target has been set by the Turkish Government for the year 2018: a total of 750 MWe for power production (at present it is about 400 MWe) and 4,000 MWth for heating (currently slightly less than 3,000 MWth). Moreover, the targeted geothermal electricity production amount for 2023 has been announced as 1,500 MWe .

To strengthen its presence in this market Turboden, established its daughter company Turboden Turkey ORC Turbo Jeneratör Sanayi Anonim ?irketi, in Ankara.

The company will be the pillar for Turboden continuous growth in the Turkish market, fully supported by Mitsubishi Heavy Industries. By means of its daughter company, Turboden will allow the access to the local content related incentives provided by the Turkish Government for renewable energy generation (both biomass and geothermal).

The brand-new local facility has already completed the development and construction of its first Turkish-made turbine, that will been delivered to AFJET A.?. – a geothermal developer – at the beginning of 2016.