Value creation from geothermal fluids beyond batteries for Tesla

Geothermal fluids have mostly been associated with power generation, but there have been efforts to extract additional value beyond heat from the mineral-rich content, e.g. for batteries of Tesla's planned new Gigafactory.

With news on new battery manufacturing facilities, or the so called Gigafactory, planned by U.S. based electric car maker Tesla, has been making news lately. One fact that is mentioned but is not receiving much attention, that the tremendous amounts of Lithium needed for the batteries are expected to be derived from geothermal brine. In our article “Value Creation beyond Electricity” in the first issue of our Think GEOENERGY Magazine published in September 2013, we talk about these operations and other “mining” efforts aimed at deriving value out of geothermal brine.

In 2013, the geothermal energy industry celebrated 100 years of commercial power generation at Larderello in Tuscany, Italy. Piero Ginori Conti, who started operating the first commercial geothermal plant in 1913, was – and this is not widely known – head of a company that derived boric acid from geothermal steam.

There has always been an interest in looking to derive valuable minerals from geothermal brine, but are there any examples today? Can mineral extraction become a profitable side business to geothermal power generation?

In the past, some companies, mainly in the U.S., have been active in mineral extraction from geothermal brines, particularly between the 1960s and 1980s. However, experimental, pilot and commercial projects have also derived minerals from brine in Mexico, New Zealand, Italy and Iceland.

When geothermal fluids interact with hot rocks, the fluids become saturated with various minerals through a chemical reaction. The composition of these resulting fluids is determined by the composition of the rocks, the chemical composition of the initial fluids, and temperature and pressure during the interaction of fluid and rock mass.

Despite various efforts and projects to commercially extract minerals from geothermal fluids, there is only one promising commercial-scale project. Based in the Salton Sea area of California, Simbol Mining Corporation received a US$3 million grant from the U.S. Department of Energy and is itself investing $6.7 million in a project to develop the company’s initial com- mercial mineral extraction facility. The project will utilize geothermal fluids derived in the pro- cess of geothermal power generation co-located at EnegySource’s John L. Featherstone (Hudson Ranch I) geothermal power plant.

Simbol Materials is planning to derive chemicals needed in the production of batteries (lithium, manganese and zinc) from the Salton Sea hypersaline geothermal reservoir located in Southern California. The company expects that the geothermal fluids from each 50 MW plant will be able to produce up to 16,000 tons of lithium carbonate equivalent, 24,000 tons of electrolytic manganese dioxide and 8,000 tons of zinc metal. Simbol Materials aims to demonstrate with its project the technical and economic feasibility of geothermal mineral extraction.

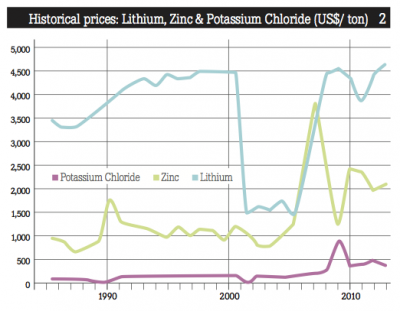

Graph: Historical prices for Lithium, Zinc and Potassium Chloride, US$/ ton (Data: USGS)

History

Looking historically at the projects that either did or at least tried to derive minerals from geothermal fluids, it is relatively obvious that the vast majority of projects never went much beyond the experimental or feasibility phase. There have also been only a limited number of pilot plants. Worldwide, only four projects ever reached a commercial production stage. The only ongoing project now is the Salton Sea project by Simbol Mining.

The United States was one of the first countries to start investigating byproducts from geothermal operations, mostly in the 1960s, but only two plants ever reached commercial operation. One of these two plants was developed and operated by Morton International in the Imperial Valley, California. It produced small amounts of calcium chloride, potassium chloride and other salts, but due to a drop in salt prices in the late 1960s, production was stopped.

In the 1970s, two water desalination projects were developed, but never reached a commercial stage. A study established geothermal desalination to be a feasible but uneconomical concept due to the specific conditions in New Mexico.

One of the companies that has been very active in mineral extraction is CalEnergy. In 1998, the company built a small demonstration plant at its Elmore geothermal plant. For a ten-month period, it successfully produced 41,000 lbs. of high-grade zinc. In 2002, CalEnergy set up another plant at the Salton Sea with the goal of producing 30,000 metric tons of 99.99-percent pure zinc, but due to technical problems, the company shut down the project in 2004.

Co-funded by the California Energy Commission and the U.S. Department of Energy, the Lawrence Livermore National Laboratory conducted a pilot-scale demonstration of silica extraction at Mammoth Lakes in 2000. The project aimed to demonstrate the technical and economic feasibility of metal and mineral co-production of silica from geothermal fluids. The economic analysis from the results of the demonstration showed the feasibility and favorable rates of returns. The technology is now being utilized by Simbol Mining Corporation at its Salton Sea project.

Around the same time, the U.S. Department of Energy’s Geothermal Technology Program carried out a study at Coso in California, and Dixie Valley and Steamboat Springs in Nevada. The goal was to obtain more information about the extraction of silica, but there is no information available about the current state of this study.

In Mexico, government-owned Fertilizantes Mexicanos (Fertimex) established a pilot project at the Cerro Prieto geothermal power facilities in the 1970s. The plan was to process potassium chloride with a target of 80,000 tons per year for the production of fertilizers. During the final construction phase, the international prices for potash collapsed and the project was abandoned.

The possibility of silica extraction was explored in a pilot plant at the Wairakei geothermal power plant in New Zealand in the mid-1990s. A study carried out on the project concluded that the production of silica would be possible but there were concerns about the amount of aluminum and calcium and their impact on the final product.

In Italy, the extraction of chemical products goes back to the 11th century, but there was no geothermal association until the early 1980s when a chemical factory was set up in Larderello that extracted boric acid from geothermal fluids. The time between 1850 and 1975 was the most productive and commercial phase for boric acid production. In the 1920s other products, such as sodium perborate, ammonium carbonate and carbonic acid, were extracted from geothermal fluids.

In 1970, Japan set up an experimental project to recover lithium from geothermal brine with initial successful results. The project was carried out by the Department of Environmental Science, Department of Metallurgy and the Kyushu Institute of Technology in the Hatchobaru and Othake areas in Kiushu.

Other projects, such as in the Cheleken area of western Kazakhstan in Russia, never reached large-scale production. In Kenya, a project extracted CO2 from shallow geothermal wells for making dry ice, and a demonstration project on Kimolos Island in Greece showed the technical feasibility of seawater desalination.

In 1979, a pilot plant in Iceland was built and operated for several years, producing sodium chloride as a fishery salt (production of salted cod). On the basis of this experimental plant, a bigger one was erected in 1983 under

the name of Reykjanes Geo-chemicals with the purpose of producing sodium chloride, potassium and calcium chloride. The plant increased its production through the 1990s, but after five years of operation, the plant was closed due to technical problems and other factors. A new company, Arctic Sea Salt, plans to start production of health salt at Reykjanes in 2014, with a newly patented method and an estimated future capacity of 30-50,000 tons/year.

Other projects have been mentioned for Ethiopia and Chile, but no further details are currently available.

Applications and costs

In a paper by Leon Lehr, “Potential for by-product recovery in geothermal energy options” (1982), it is described that “economics of mineral extraction [from geothermal fluids] are driven by geothermal fluid characteristics, specific by-product(s) to be recovered, quantity, quality, value, marketability, type of geothermal energy conversion system used, size of energy facility, regulatory waste treatment and disposal requirements.”

Around 40 minerals have been analyzed, of which the main three have been identified as zinc, lithium and potassium chloride, followed by silica, sodium chloride, calcium chloride, and lead. The economic feasibility of mineral extraction is highly dependent on international mineral prices. Both declining prices and sudden fluctuations have been challenging for extraction projects. As an example, potassium extraction projects in Mexico and the United States in the 1960s and 1970s were abandoned due to a sharp price drop for potassium at the time. Currently, prices for the main minerals have seen an increase, particularly around the year 2000.

Potassium is an essential mineral for agriculture, and most of the potassium chloride produced today is used for making fertilizers. Zinc has been one of the few minerals that has seen commercial extraction. At CalEnergy’s zinc extraction plant, operations only came to an end after technical problems. From 2000 until today, the price for zinc has more than doubled. Zinc is today used most for galvanizing, in zinc-based alloys, but also in brass and bronze, among others.

Lithium is probably the most interesting mineral currently and it would not be surprising if it now saw a resurgence in geothermal fluid extraction. Lithium is a key element in the production of electric batteries, and thereby a crucial ingredient in the growing use of electric cars, as well as in other applications. It is therefore the object of great commercial and government interest, resulting in a sharp increase in prices for the mineral. Lithium is also used in other applications, such as lubricating greases, casting, air treatment and others. With an expected doubling of demand for lithium in the next 7-10 years, prices will very likely continue to go up.

New times ahead?

Only four plants have so far entered into commercial operation: one in Italy, one in Kenya, and two plants in the United States. There are two main obstacles that have been holding back further development. The price volatility for minerals has been one of the key reasons behind the failure of plants, but the lack of maturity in technology used in mineral extractions from geothermal fluids has been another one.

With the increasing demand for specific minerals and increasing prices for those, mineral extraction from geothermal fluids is now an attractive field again. New technology development and the recent project for lithium extraction have attracted new investors and could mean a revival of some of the previous efforts by the industry to derive value from geothermal fluids beyond electricity generation. In short, there might be a second chance to create a valuable side business for geothermal operations.

This article was originally published in Think GEOENERGY Magazine, Issue 1 (2013), co-authored by Abraham Ormad and Alexander Richter of ThinkGeoEnergy, also including a detailed list of geothermal brine byproduct – recovery and investigation projects.

You can subscribe to the bi-annual Think GEOENERGY Magazine via magazine.thinkgeoenergy.com