10 years in Kenya – the geothermal success story of GEG

Looking back in pride, Icelandic GEG reflects its 10 year history in Kenya and its partnership with KenGen on the development of wellhead geothermal power generation.

With the win of a tender for a 5.5 MW geothermal pilot plant in late 2009, Icelandic geothermal developer and technology company GEG (then Green Energy Group) entered the international geothermal energy market with the new concept of modular geothermal development with small geothermal wellhead power plants. In an article on its website, the company provides a background on how from the first plant it has developed since a total of 15 geothermal wellhead plants.

From those early beginnings and the start of construction in 2010/ 2011, GEG has today delivered a total of 85.6 MW in geothermal power generation capacity in Kenya and Iceland. For KenGen (Kenya Electricity Generating Company PLC), GEG built 15 wellhead power plants as well as delivered and set up several substations.

Of the sixteen plants built by GEG, fifteen of those were built for KenGen, as well as one for Landsvirkjun, in GEG‘s home country of Iceland.

A Timeline of GEG’s Impact in Kenya

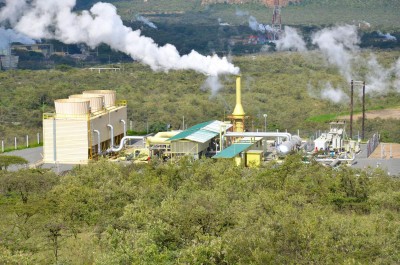

It has now been ten years since GEG’s pilot plant began commercial operations. Impressively, between April 2011 to March 2017, GEG built one 5.5 MW pilot plant along with four 6.4 MW and ten 5 MW geothermal wellhead plants on seven different well pads at the Olkaria geothermal field in Kenya.

These plants today represent around 12% of the installed geothermal power generation capacity of KenGen and around 9% of the total geothermal power generation capacity of Kenya (and Africa), showcasing GEG’s significant market impact.

Implementing this strategy has helped utilise geothermal resources at Olkaria efficiently with limited impact to the natural environment. All the components for the plants were shipped in 40ft marine containers to the sites, removing the need for extensive additional road construction as is typically required for the drilling rigs which drill the wells on-site.

The wellhead plants also allow for the utilisation of remote wells, with better efficiency in the use of the resource on site and the flexibility to adapt the power generation to the individual wells.

In the beginning of the collaboration between GEG and KenGen, the efficient way challenges and limitations with the initial 5.5 MW power plant were tackled set the bar for this successful partnership. For example, a change in the turbine manufacturer led to the installation of new, more effective turbines, and erecting new high-voltage evacuation lines solved the instability of the previous medium-voltage lines.

KenGen’s foresight in exploring and problem-solving aspects of this smaller scale distributed development approach — which allows for easier financing, faster deployment, and therewith quicker return — must be applauded.

This modular approach to development provided a faster and more efficient way for KenGen to apply funding and to create a more streamlined income path from geothermal power production.

The Views from GEG

“We are incredibly proud of the partnership with KenGen and the company entrusting us in the implementation of this revolutionary modular wellhead power plant strategy. With the pilot plant and additional 14 plants then built by GEG, either as stand-alone plants or in clusters of up to 5 units, we not only gained a lot of insight, but also the experience needed for our international expansion. With the work at Olkaria, we not only created a faster path to revenue generation, but also helped to mitigate up to 2 million tonnes of carbon emissions from fossil fuel-based generation in Kenya”, said Sigthor Jonsson, CEO of GEG.

“We are very much looking forward to continuing to work with KenGen in Kenya, as well as exploring further geothermal wellhead plant development in Kenya together with KenGen”, states Snorri Einarsson, CTO of GEG.

The View from KenGen

In a case study presentation on the geothermal wellhead power plants of Kenya Electricity Generating PLC (KenGen) at the Iceland Geothermal Conference in 2018, Peter Chege, Assistant Manager, responsible for the Geothermal Wellhead plants at KenGen, provided an insight into how the company successfully developed and implemented its geothermal wellhead strategy.

In the 2018 presentation, the various challenges (and subsequent solutions) of the modular approach taken by GEG and KenGen, were also outlined. These ranged from issues related to mobility to those involving limited reinjection. In the case of the mobility challenge described in the presentation, solutions included employing various design improvements and redesigning of specific components, along with utilizing containerized plant systems (for example, substations and cooling tower cells).

The limited reinjection of modular plants was effectively addressed by means of locating several plants on one single well pad. This way, a closer connection to the closest reinjection system was achieved. The presentation concluded by stating that the wellhead implementation strategy would be fast-tracked, and that it would undergo continued improvements to further address specific challenges.

Based on the “successful implementation, KenGen wants to fast track the wellhead implementation strategy and a continued improvement of the strategy. With its experience, KenGen also believes it can provide consultancy/project implementation to other utilities in the region in partnership with GEG”, said Peter Chege at the conference.

Today, the plants provide a significant annual revenue to KenGen, helping the company to repay the investment into the plants, said Peter Chege in his presentation at the conference in 2018.

GEG’s Plans for the Future

With its unique business model, GEG pioneered the approach of delivering turnkey modular geothermal power plants as a complete package, from the well to the connection to the transmission line. GEG designs, engineers, and provides the necessary construction work, assembly on-site, and commissioning in one package. This has enabled GEG to speed up development and support a faster return on investment for geothermal projects, while providing flexibility in the build-out of the plants.

The company has shifted focus from the delivery of a complete turnkey power plant development package to clients, to a new development approach through joint ventures with international partners for more efficient implementation.

Following this shift, GEG is now acting as a development partner and investor in projects, combining its project delivery experience with the exploration knowledge of internationally acclaimed geothermal exploration service partners.

There has been a lot of work going on in the background and GEG will be pleased to be able to share details about its ongoing project development efforts globally.

What is the Modular Approach?

Traditional geothermal power plant development has typically been focused on large scale development requiring an extensive drilling program, steam gathering and delivery systems, and then the development of large-scale geothermal plants.

This development has been taking all from 7 to 10 years to reach completion, contributing to a low average annual generation capacity growth. The traditional approach entails several challenges. Among them are the resource risk, both in the context of proving the resource’s viability for power generation as well as the financing risk of being able to fund the extensive drilling campaign and the corresponding large-scale power plant and related infrastructure.

Therefore, the development of projects in steps in a modular approach is seen as a tool to address some of these aspects. Smaller plants, or specifically wellhead plants, could be built right after the drilling of the initial wells and allow for a faster set up of plants and the production of electricity. This not only allows for better efficiency due to the plant being streamlined to utilise the resource of these wells on site, but potentially provides electricity to the further drilling campaign in the field, and most importantly speeds up the generation of revenues from the operation.

As a result, the financing of the development of a field looks completely different. The income from revenues could be used against getting a loan for further development instead of having to rely on equity funding. In a presentation at the Iceland Geothermal Conference in 2018, GEG shared details on how a modular approach to development can help decrease the equity requirements for geothermal project development. You can access an overview here.

If the resource is proven it can supply that small plant, if it does not then the financial burden is not as big as if a whole large-scale drilling campaign fails. At the same time, it could allow efficient scaling up of development if there are better resources found. A modular approach also allows development in more remote locations with a lower footprint per installed MW of generation capacity. This clearly results in a lower impact on the environment surrounding the locations of the plants.

Awards and Certifications

For its pioneering work on geothermal wellhead power generation, GEG received two prestigious awards. In 2014, the company was named a New Energy Pioneer by Bloomberg New Energy Finance (BNEF), which highlighted the “game changing innovation“ of the awardees from a broad range of industries on energy efficiency, renewable energy, innovative finance and more.

In 2015, GEG was the runner-up to the European Geothermal Innovation Award by the European Geothermal Energy Council, which emphasized the “innovative business model and global technology approach for small-scale geothermal power plants in high enthalpy zones” by GEG.

Through the work on the Olkaria geothermal wellhead plants, GEG then also developed substation set ups for easy transport and timely set up with its plants. This helped KenGen to connect the plants quicker to the local grid. It has also supported GEG to expand its product offering beyond the plant and construction thereof, and includes today larger substations and mobile substations that can be set up swiftly with the geothermal wellhead plants.

Our Impact for Local Communities

Geothermal energy development involves local opportunities as well as challenges. GEG understands the importance of sustainability in the context of local development. With the approach of localised wellhead development, the company operates on a low footprint for plants minimizing the visual and structural impact to the environment to the benefit of local populations.

In the development of its 15 plants in Kenya, GEG was engaged with the local workforce both for civil works, construction, and training of operators for KenGen on site. However, the company also understands its responsibility beyond the construction of the plants. In Kenya, GEG not only trained local staff on the operation of the plants it had installed for KenGen, but also engaged with the local population, supporting among others a local school with the donation of books upon learning of a shortage of teaching materials.

“Working locally with the Maasai Community has been an elementary part of our activities at Olkaria and it was humbling to see how the provision of these books was so positively received by the school children and their teachers”, said GEG‘s local project manager at the time. On a smaller scale, the company also engaged in wildlife conservation, supporting among others a local elephant conservation center.

Summary

“GEG is looking back at the past ten years with pride of its partnership with KenGen. Helping the company on the development of 15 geothermal wellhead power plants and thereby implementing KenGen‘s strategy on localised modular geothermal plant development has been an honour”, said the company in a statement to ThinkGeoEnergy.

It clearly put the concept of modular development with geothermal wellhead power plants on the map. There are several efforts to apply a similar concept to the development of geothermal projects, but so far, no company has the experience in the development, construction, or operation of these plants.

The operation of the wellhead plants at Olkaria has gone smoothly and with good experience, which resulted in the continued cooperation of GEG with KenGen in relation to operating and maintenance and technical support, as well as for potential further wellhead development in Kenya.

With its adapted business model, GEG has now moved beyond the pure delivery, construction, and commissioning of geothermal wellhead plants, also engaging with partners on development of its own projects. These are exciting times in the geothermal sector, and a unique business model approach like that of GEG clearly has a role in the further development of geothermal energy projects around the world.

Source: GEG Power