Project outcomes of CHPM2030 project – Combined (geothermal) heat, power and metal extraction

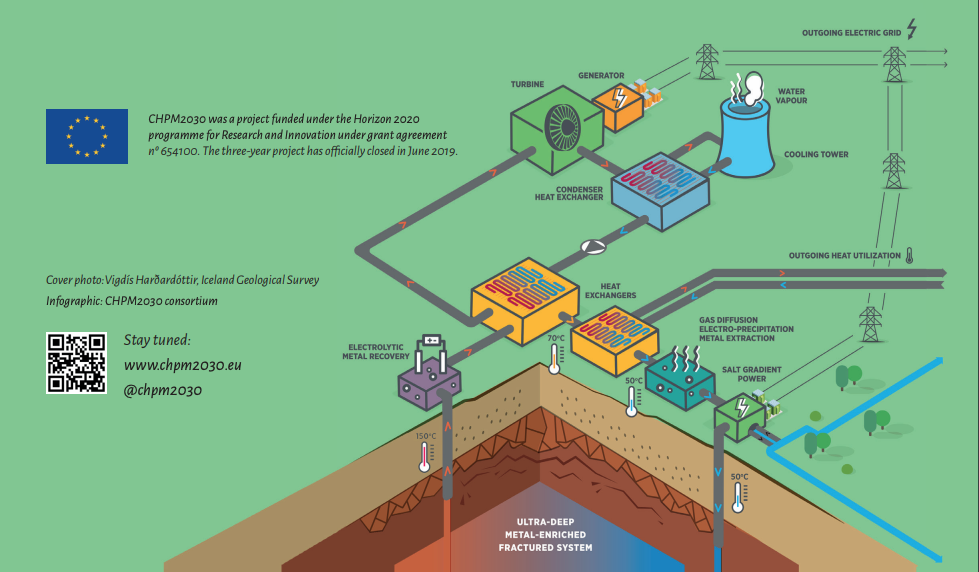

In its final outcome factsheet, the CHPM2030 project has shared details in reports on the different results from the activities of the project partners. The CHPM2030 project was set up to develop a novel technology, which combines deep geothermal energy production with metals extraction from the geothermal fluid in a single interlinked process (Combined Heat Power and Metals – CHPM).

The CHPM2030 project has finished, and has published a final impact factsheet. This document concisely summarises the project outcomes during the years, providing a timeline of development of the Consortium.

Many of the project results were already presented at CHPM2030 Final Conference in the framework of the EuroWorkshop “Geology and the energy transition” on 23 May 2019 at the Science Centre of Delft University of Technology (the Netherlands).

The “Combined heat, power and metal extraction” CHPM2030 project was set up to develop a novel technology, which combines deep geothermal energy production with metals extraction from the geothermal fluid in a single interlinked process (Combined Heat Power and Metals – CHPM). In order to improve the economics of deep geothermal energy development, the project has investigated possible technologies for mobilising metals from metal-bearing geological formations with geothermal potential at a depth of 3 to 4 km, and potentially even deeper, and recovering metals from the geothermal fluid at surface. Thanks to the research by the CHPM2030 Team, the co-production of energy and metals might become possible and may be optimised according to market demands in the future.

In the factsheet shared this month, the project shares highlights of the project since its inception in 2016. Here the final results shared for 2018/ 2019.

- It was proved that metals can be successfully electrodeposited at elevated pressure and temperature (up to 300 °C and 238 bar); higher pressures and temperatures lead to higher recovery rates. Read more: D3.1 Report on performance and design criteria for high-temperature, high- pressure electrolysis.

- It was proved that gas-dif fusion electroprecipitation and electrocrystallization (GDEx) is a novel way to recover metals from dilute solutions. The patent of this process has been granted in Europe. Read more: D3.2 Report on performance, mass and energy balances and design criteria for gas-dif fusion electroprecipitation and electrocrystallization.

- It was proved that GDEx allows nearly full recovery of the relevant metals present, and selectivity can be achieved. The GDEx experiments are up-scalable and work for most of the critical raw materials. Preliminary economic feasibility calculations show positive results. Read more: D3.2 Report on performance, mass and energy balances and design criteria for gas-dif fusion electroprecipitation and electrocrystallization

- It was proved that the presence of multivalent ions in the geothermal brine does not eliminate the potential for salinity gradient power generation by reverse electrodialysis (SGP-RE), though a reduction in power was noted. However, the extraction of electrical energy was enhanced significantly by increasing the brine temperature. Read more: D3.3 Report on performance, energy balances and design criteria for salt gradient power reverse electrodialysis

- A mathematical model framework was created based on the technology component-level models, which enables linking downstream and upstream geothermal engineering subsystems. Read more: D4.2 Report on CHPM process optimisation (link not available)

- The overall model can be used to study different scenarios, perform simulations, and develop optimisation and other kinds of system analysis. Read more: D4.2 Report on CHPM process optimisation (link not available)

- A decision support tool has been developed for the economic feasibility assessment allowing users to simulate revenue streams from both energy and metal extraction levels. The tool will remain accessible after the project lifetime through the MinPol website. Read more: D5.3 Self-Assessment Tool

- Best practices have been suggested to companies planning to run CHPM plants for minimising the social and environmental impacts of the technology. Read more: D5.5 Environmental impact assessment framework

- A wide array of convergent technologies and relevant issues were defined (linked to CHPM exploration, development, operation and market) that can support the implementation of the technologically challenging CHPM scheme by 2030/2050. Read more: D6.1 Report on Emerging and Converging Technologies

- Detailed studies on the potential pilot sites and European-level databases provide the foundations for the implementation of pilot CHPM projects by 2030. Read more: D6.2 Report on pilots – compiled from 5 reports

- Roadmaps for the implementation of future CHPM projects have been provided for 2030 and 2050 time horizons, including actions, targets and milestones. Read more: D6.3 Roadmap for 2030 and 2050

Read the full Impact Fact sheet below, or download it here.

Source: CHPM2030