EU DeepU project explores non-mechanical drilling technology for deep geothermal

A recent webinar by the DeepU project examines the state of geothermal deep drilling technologies and showcased the potential of laser drilling.

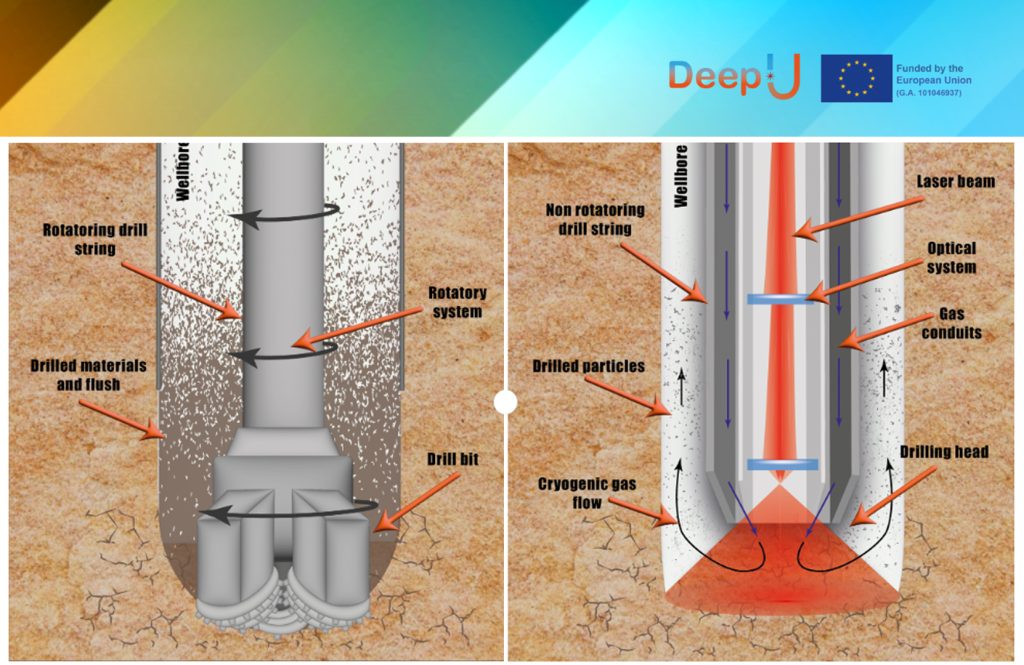

Traditional drilling methods primarily rely on mechanical force, utilising a rotatory system to grind and crush rock – a process that can be both time-consuming and costly. To overcome these limitations, the DeepU project introduces an innovative drilling technology that harnesses the power of laser energy combined with cryogenic gas, enabling rock fracturing with unprecedented speed and precision.

The overall aim of DeepU is to develop a deep (>4 km), closed-loop, vitrified, waterproof, non-cracked U-tube heat exchanger by integrating laser and cryogenic gas into a single cutting-edge drilling solution.

The proposed technology is being tested at the laboratory scale in different rock types to verify its ability to liquefy and vitrify rock, ensuring the borehole is ready for heat exchange immediately after drilling. Laboratory demonstrations provide crucial data to assess the technological, environmental and economic sustainability of the proposed solution, while also defining its potential and commercial viability.

The high-risk innovation presented in DeepU has the potential to make geothermal energy system accessible everywhere in a targeted and demand-oriented manner, offering a complementary approach and an alternative solution to traditional energy storage and production, decentralising the power supply also in areas where this is currently deemed uneconomic.

DeepU has been funded by the European Commission under the EIC Pathfinder Programme (G.A. 101046937) as part of Horizon Europe. Eng. Luc Pockelé coordinates the project from the RED srl in collaboration with partners from four countries: the University of Padua (Italy), Prevent GmbH (Germany), Fraunhofer IAPT (Germany), GeoServ (Ireland), The Wroclaw University of Science and Technology (Poland), and the Consiglio Nazionale delle Ricerche IGG (Italy). The project will run until October 2025.

Does deep drilling need a revolution?

Just recently, the DeepU project held a webinar titled “Does deep drilling need a revolution?” The webinar brought together experts and stakeholders to examine the current state of deep drilling technologies while initiating a discussion on the breakthroughs necessary to access ultra-deep geothermal resources. Central to the conversation was the pioneering technology proposed by DeepU – its approach combines high-power lasers and cryogenic gas to penetrate the most challenging rock formations.

The project partners showcased cutting-edge, innovative drilling technologies while emphasizing the advantages of non-mechanical drilling. They shared significant findings from the DeepU project that demonstrate, on a laboratory level, the potential of laser drilling technology to address the limitations of conventional methods.

The research investigates how lasers interact with rock, revealing that thermal spallation, melting, and vaporization occur simultaneously, albeit with varying intensities based on rock type, power density, and irradiation duration. Notably, thermal spallation is the most promising to produce usable diameter wells, with drilling rates ranging from 5 to 15 meters per hour.

The team has selected supercritical nitrogen as the flushing medium for deep borehole drilling due to its thermodynamic properties and effectiveness in removing cuttings. They developed a numerical model to determine the necessary pressure and flow rates for different borehole depths, which is being validated through a dedicated test rig.

The proposed system involves storing liquid nitrogen, compressing it to high pressures (up to 350 bars), and delivering it down the borehole through a specially designed channel with vacuum insulation. Among the challenges discussed regarding the technology is the need for integration with existing drilling equipment and practices.

The presentations and the recording of the webinar are available on the project website.

Source: DeepU project