Geomechanics: The Backbone of Geothermal Energy

The study of geomechanics plays a crucial yet underappreciated role in geothermal energy, from wellbore stability to effectivity of hydraulic stimulation.

Geomechanics, the study of the mechanical behavior of rocks and soils, plays a crucial role in developing and operating geothermal energy systems, particularly in Enhanced Geothermal Systems (EGS) and Superhot Rock (SHR) projects. By understanding the stress state, rock strength, and fluid flow behavior in the subsurface, geomechanics helps to optimize well design, hydraulic fracturing, and reservoir management (Liu et al., 2022).

While this is conceptually understood, there is still some confusion of just how valuable and extensive geomechanics studies can be within the geothermal industry. In the worst case scenario, no geomechanical model or an incorrect model could lead to improper wellbore treatment and wellbore loss, in the best case scenario, a proper geomechanical model can lead to a successful, optimized, profitable geothermal power plant.

This guest article written by TEVERRA highlights the key geomechanics applications in the geothermal industry, including wellbore stability, hydraulic fracturing, the specific challenges of superhot rock (SHR) geothermal systems, casing design, proppant selection, and thermal stress analysis.

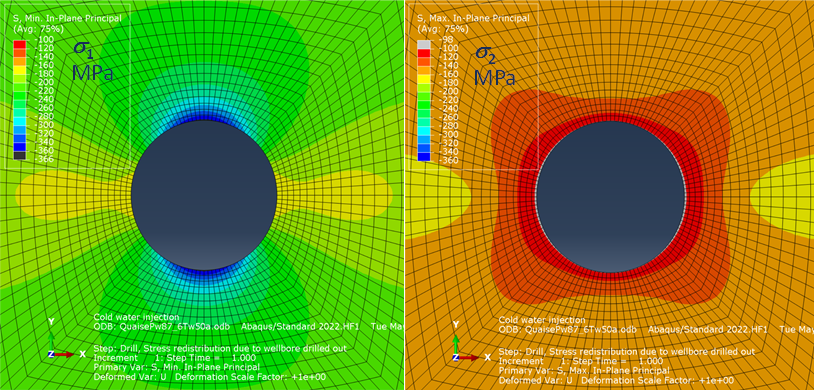

Wellbore Stability

Wellbore stability is vital in successfully developing and operating geothermal energy projects, particularly in high-temperature and high-pressure environments. Extreme temperatures, high fluid pressures, and thermal stresses can significantly impact wellbore integrity.

Geomechanical analysis is essential to predict and mitigate potential stability issues, including borehole collapse, borehole enlargement, and lost circulation, to ensure the long-term viability of geothermal wells. By optimizing drilling fluid design, casing, cementation programs, and wellbore completion strategies, engineers can enhance wellbore stability and maximize geothermal energy’s economic and environmental benefits (Madyarov et al., 2021).

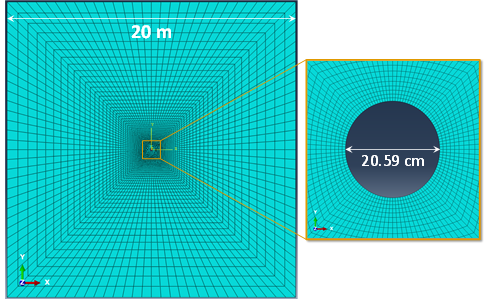

The figure above shows an example of wellbore stability simulation model results: maximum principal stress (left) and minimum principal stress (right) distributions around the wellbore with hydrostatic pressure in the wellbore.

Hydraulic Fracturing

Hydraulic fracturing, a well-established technique in the oil and gas industry, has been adapted for use in the geothermal industry to enhance reservoir permeability and improve energy extraction. By injecting high-pressure fluid into the subsurface formation, hydraulic fracturing creates complex fracture networks that facilitate the flow of geothermal fluids to the production well and efficient heat extraction from the reservoir.

However, the 20 years of hydraulic fracturing experience in the oil and gas industry shows that not all hydraulic fracturing designs are successful. Geomechanical modeling is crucial in optimizing hydraulic fracturing operations by predicting fracture propagation, minimizing induced seismicity, and maximizing reservoir productivity. Careful consideration of factors such as rock properties, in-situ stress state, and fluid injection parameters is essential to ensure the success of hydraulic fracturing treatments in geothermal reservoirs (Porlles & Jabbari, 2022).

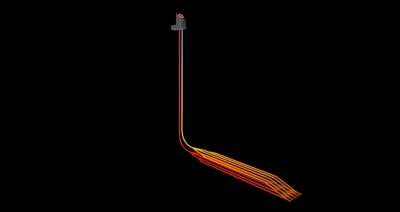

Superhot Rock (SHR) Geothermal Systems

Superhot Rock (SHR) geothermal systems offer a promising avenue for harnessing vast amounts of geothermal energy from deep, high-temperature rock formations (Houde et al., 2021). These systems involve drilling deep wells into the Earth’s crust to access hot rock, fractured to create a reservoir. Water is injected into the fractures to extract heat, which is then used to generate electricity.

While there is significant opportunity, the extreme temperature and pressure conditions associated with SHR systems pose significant technical challenges, including wellbore stability, induced seismicity, and corrosion. Advanced drilling technologies, hydraulic fracturing techniques, and robust wellbore design are essential to overcome these challenges, many of which cannot be tested until SHR drilling commences.

By understanding the geomechanical properties of the rock formations and simulating drilling and wellbore completion in SHR conditions, the industry can progress towards optimizing the design and operation of SHR systems. Once successful, SHR will unlock the enormous potential of this clean and sustainable energy source (Cladouhos & Callahan, 2024).

The figure above shows a geomechanical numerical model (geometry and mesh) performed to test wellbore stability of a hypothetical superhot rock wellbore.

Proppant Selection

Proppant selection in the geothermal industry involves choosing solid, granular materials pumped into hydraulic fractures to maintain their permeability and enhance fluid flow.

Unlike conventional oil and gas applications, geothermal reservoirs often experience higher temperatures and pressures and exposure to corrosive fluids. These operating conditions are incompatible with many oil and gas industry proppants; therefore, proppants must be carefully selected to withstand these harsh conditions and maintain their integrity over time.

Key factors to consider in proppant selection include proppant lab analysis using geomechanics crushing test, particle size distribution, strength, thermal stability, chemical resistance, and cost-effectiveness. By optimizing proppant selection and placement, engineers can improve the performance of geothermal reservoirs and maximize energy extraction (Liu et al., 2023).

Thermal Stress Analysis

Thermal stress analysis in the geothermal industry involves evaluating the impact of temperature gradients on the mechanical behavior of rock formations and wellbore components. High-temperature differences between the hot reservoir rock and the cooler drilling fluid or injected water can induce significant thermal stresses, leading to potential issues such as wellbore instability, rock fracture, and reduced reservoir productivity.

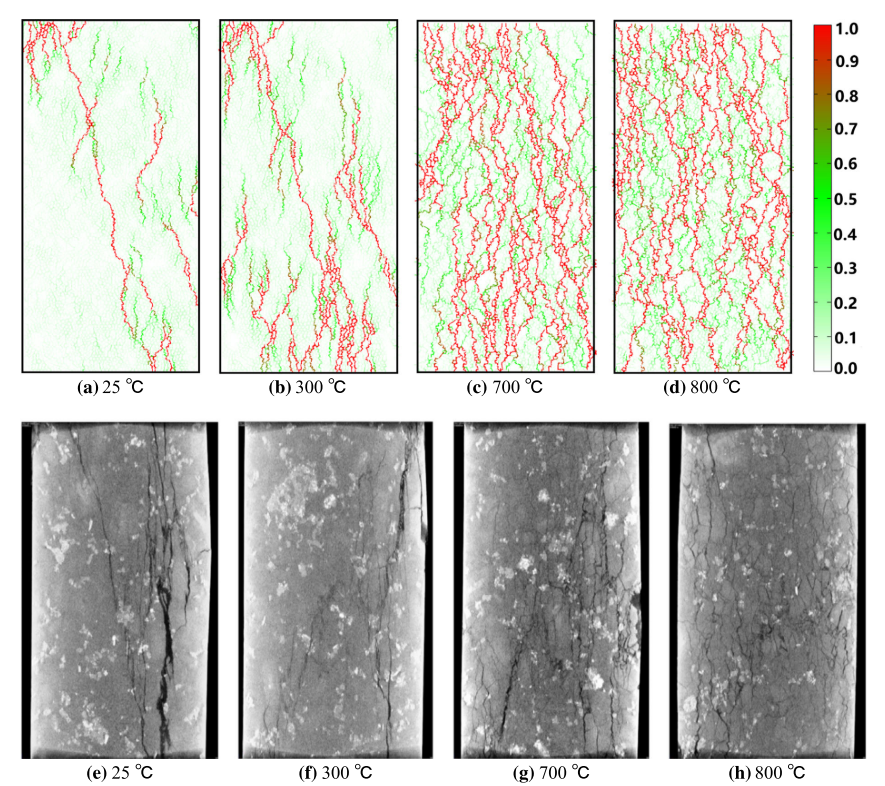

Geomechanical modeling techniques, including finite element analysis (FEA), simulate thermal stress distribution and assess its impact on wellbore integrity and reservoir performance. By understanding the thermal stress regime, engineers can optimize well design, casing selection, and production strategies to mitigate the risks associated with thermal expansion and contraction (Zhou et al., 2022). Geomechanics helps us to understand crack patterns of the numerical model are shown in figure below.

The Future of Geomechanics in Geothermal Energy

The future use and application of geomechanics in geothermal energy could unlock immense resource potential, with technological advancements and a growing emphasis on sustainable energy sources. By integrating advanced numerical modeling techniques, machine learning, and real-time monitoring, geomechanics will be crucial in optimizing well design, improving drilling efficiency, and enhancing reservoir productivity.

As the industry continues to explore new energy extraction approaches, such as enhanced geothermal systems (EGS) and superhot rock (SHR) technologies, geomechanics will be essential in addressing complex challenges related to wellbore stability, hydraulic fracturing, and reservoir management (Jia et al., 2022).

By understanding the intricate interplay between geological, mechanical, and thermal processes, geomechanics will pave the way for the sustainable development and utilization of geothermal energy.

References

Cladouhos, T. T., & Callahan, O. A. (2024). Heat Extraction from SuperHot Rock-Technology Development.

Houde, M., Woskov, P., Lee, J., & Oglesby, K. (2021). Unlocking Deep SuperHot Rock Resources Through Millimeter Wave Drilling Technology. GRC Transactions, 45.

Jia, Y., Tsang, C.-F., Hammar, A., & Niemi, A. (2022). Hydraulic stimulation strategies in enhanced geothermal systems (EGS): a review. Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 8(6), 211. https://doi.org/10.1007/s40948-022-00516-w

Liu, S., Balushi, F., & Dahi, A. (2023). Conductive Proppants to Improve Heat Extraction. 48th Workshop on Geothermal Reservoir Engineering .

Madyarov, A., Porlles, J., Batir, J., & Soroush, H. (2021). Wellbore Stability Model for an Injection Well in SuperHot Rock Drilled Using MMW CO2 Innovation is Our Passion. www.petrolern.com

Porlles, J. W., & Jabbari, H. (2022, June 26). Simulation-Based Economical Modeling of Hydraulic Fracturing for Enhanced Geothermal System. All Days. https://doi.org/10.56952/ARMA-2022-2326

Zhou, Z., Mikada, H., Takekawa, J., & Xu, S. (2022). Numerical Simulation of Hydraulic Fracturing in Enhanced Geothermal Systems Considering Thermal Stress Cracks. Pure and Applied Geophysics, 179(5), 1775–1804. https://doi.org/10.1007/s00024-022-02996-z