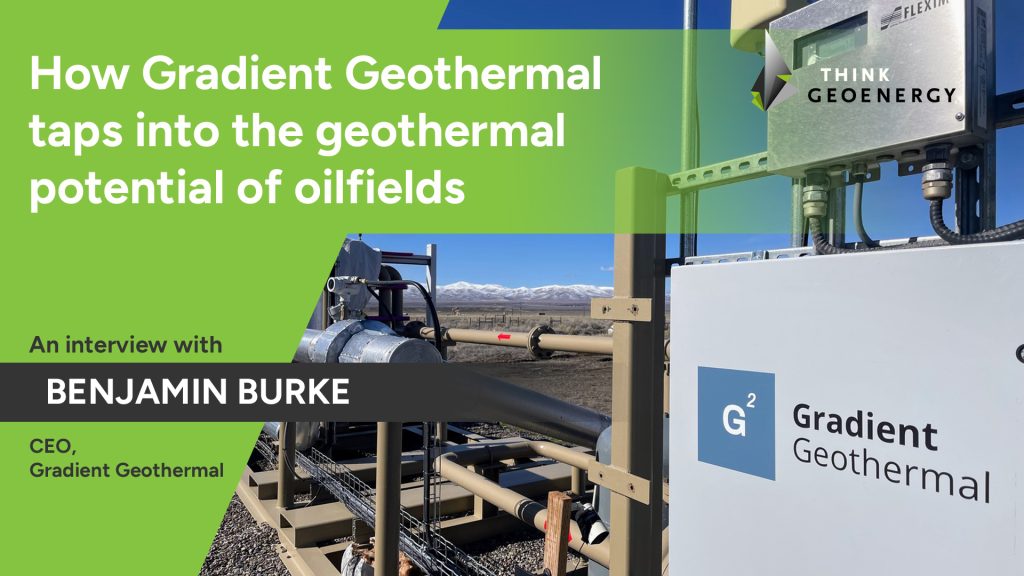

Interview – How Gradient Geothermal taps into the geothermal potential of oilfields

In this interview, Benjamin Burke of Gradient Geothermal tells us about geothermal power production in oilfields using proprietary technologies.

A lot has already been said about high drilling costs and resource discovery risk being two of the major barriers to widespread adoption of geothermal. Colorado-based Gradient Geothermal is overcoming these barriers with a novel yet reasonably practical approach – producing geothermal power from produced fluids of existing wells in oil and gas fields.

The company had recently announced the deployment of their HXC Geothermal System technology to generate geothermal power at the oil and gas assets of Chord Energy in North Dakota. Sufficiently intrigued, we caught up with Benjamin Burke, CEO of Gradient Geothermal, to learn more about their technology, business model, current projects, and the unique position that the company occupies within the geothermal industry.

Harnessing the geothermal energy of oil and gas fields

The business of Gradient Geothermal (Gradient) can be briefly summarized as the deployment of modular, mobile geothermal units into oil fields to generate power and provide cooling services. This fulfills two objectives – fluid cooling, which consumes a lot of power in oil and gas production, and geothermal power generation. With the technology of Gradient, operators can benefit from carbon emissions reduction, reduced utility costs, and the availability of a more resilient power source.

“In either case, we generate power, but we can really flexibly meet the goals of our clients,” said Burke. “Geothermal is a great vehicle for them to achieve all those goals.”

“For most of our clients, the geothermal power they generate on site means that they are consuming less from the grid, or will need to generate less power from diesel or natural gas. There is value in terms of both offsetting carbon emissions and having affordable and reliable power generated onsite.

Gradient is also exploring the possibility of supplying heat from their technology under a cascading use model, where residual heat from power generation can be utilized by the operator or a partner. A partner under this model can be in the industry of agribusiness, aquaculture, industrial drying, or any of a number of conventional direct heat users. There is a limitation in that these facilities have to be located close to the oilfield, but the company is looking forward to partner with different industries.

Flexible and easy-to-deploy technology

The patented HXC sled is at the heart of the oilfield solutions that Gradient is offering. The sled comprises a heat exchanger, an ORC unit, and a dry cooler. The system was designed to be modular, ruggedized, and able to handle different types of fluid with no pre-treatment requirements. This allows the technology to be deployed in challenging fluid conditions, or even in temperatures that are not very high.

“We do work with our clients on a pre-qualification process, but the hurdle is not terribly high,” Burke commented.

The preferred areas for power generation have temperatures of over 200 °F (93 °C), but the technology can work with temperatures of at least 165 °F (74 °C). In terms of flowrate, Gradient needs at least about 2000 barrels per day, or equivalent to 3.2 liters per second for power generation. In case flowrate from one well is not sufficient, flow from several wells in an oilfield can be aggregated to satisfy this requirement. Gradient works at oil and gas wells as well as central facilities in cases where multiple wells are used. However, this may present new challenges.

“Gathering fluids far from the wellbore can result in heat loss, so we work with clients to help them understand where heat loss is occurring. If fluid aggregation is a really important aspect of the project, then we work with them to help insulate the system.”

The technology is also not selective in terms of the water cut of the fluids. “We can use 100% water. We could use 100% oil or gas. We could use any ratio in between,” Burke put succinctly. The design and metallurgy of heat exchanger may need to be changed based on the composition of the fluids, but Gradient works with clients to address this engineering challenge.

The heat exchanger is the only direct point of contact between the HXC sled and the well fluids. It can handle whatever is in the fluid stream from the oilfield, whether gas or solids, and thus protects all other components of the HXC sled. In general, oilfield operators treat their fluids to mitigate scaling or precipitate out undesired minerals. Whatever chemical programs the operator may implement works well with Gradient’s technology.

“If it works for the operator, then it’s good for us. The fluid does not need to go under any special pre-treatment for our equipment.”

In terms of deployment time, initial assessment for new clients can take between one to three months depending on how fast the client would like to move. Once the unit has been customized and ready to be deployed, setting up on site takes only one day. The system can start running fairly quickly, both on the electrical side and the fluid plumbing side.

Lessons from the Blackburn site and future plans

The initial project of Gradient at the Blackburn site in Nevada operated from May 2022 to April 2024. The unit from the Blackburn site has since been transferred to North Dakota, but the Blackburn site is still active as part of the US Department of Energy Blackburn Wells of Opportunity study. This is a three-phase project with the Department of Energy which has now just moved to the second phase, which involves procurement, installation, and commissioning.

The Blackburn site is a conventional mature oil field that was discovered in the 1980s and is now over 99% water flow. There are a lot of a lot of oil fields like it around the world and in the US. The Blackburn project was a valuable learning experience for Gradient in terms of anticipating the surface infrastructure needed to scale up an oil field for geothermal power generation.

“Geothermal needs more thermal mass flow, and so there are fluid gathering systems, tanks, and separation vessels to consider,” said Burke. “We also had to consider the existing infrastructure in the field. Some of it may only need to be augmented rather than be replaced. Going through all these factors with the operator and looking at what can be augmented or replaced was a really big learning for us, and we are excited to share this with the public.”

Throughout the course of the feasibility study in Blackburn, several trials were done to optimize power generation of the 175-kW nameplate unit on site. At maximum power generation, the team was able to attain about 2/3 of the capacity of the power generation unit. The next goal for Gradient is to scale up the flow and optimize the location of the unit to attain 250 kw of net power generation or just over 300 kW of gross power generation.

The mission for the Blackburn project is to demonstrate the pathway to 1 MW geothermal power generation in an existing oilfield. Gradient has done plenty of surface and subsurface work to document the various scenarios and challenges taking oilfields across the US and scaling them up for geothermal production, or for an end-of-life oilfield to continue on as a geothermal field. “We’ve learned a ton and we are excited to share that with the DOE and the public as we go forward,” said Burke.

Projects in North Dakota

As mentioned, Gradient has since deployed their technology at an oilfield in North Dakota operated by Chord Energy. However, the company has also started work with other operators in the Basin region.

With these new projects, Gradient continues to gain more experience that help improve their technologies and processes. For instance, working with new wells can be very different from working with wells that have been around for more than 40 years. “In some cases, you can get a lot of sand flow or other kinds of debris flowing up new wells. Learning how to handle solids has been a big part of our experience.”

“Our units are very adaptable. We have no problem handling abrupt changes in flow rates and temperatures.”

Working in extremely cold conditions with geothermal fluids at temperatures below 0 °C also meant that the team had to be ready for freezing conditions in case of discontinuous flow. “The same challenges that other operators find in North Dakota in the oil and gas realm are going to be geothermal challenges as well. Everything’s great when the whole system is hot, but if the site has to shut in for a while, you have to be ready for freezing conditions. We had to work to make sure our unit was ready for those with glycol in the HXC.”

What else is in the future for Gradient Geothermal?

Gradient has some other projects currently in the pre-operations phase outside the United States. Within the US, the company is particularly excited about a thermal energy network project in Pierce, Colorado, for which Gradient received a grant from the state energy office.

Gradient will be doing a feasibility study in the town of Pierce, a small eastern plains town that has hosted an oil field since 1951. That oilfield has been played out, and now the operator is looking for another life for the field. Thus, there is an opportunity to utilize the oilfield to provide heat to local residents and businesses. This is an example where there is a very large direct thermal energy opportunity.

Additionally, the company is looking into other realms as part of their larger business plan. The company is considering going beyond the business of leasing their technology, and possibly growing into owning and operating oilfields, power facilities, and selling electricity to the grid or directly to end-users through PPAs.

Focusing on technology that already exists

Burke states that in the US alone, there are just under 2.9 million wells that are both currently operating and wells that have operated that can be re-entered. Of that, about a half million are wells that have the wellbore integrity and the heat and flowrate, possibly through aggregation, for geothermal power generation. This amounts to electricity generation potential of about 13 GW.

“We look not only at individual wells, but individual field opportunities,” Burke added. “That really covers the whole US, from the Appalachian Basin in the east, to the entire Gulf Coast Basin. There are a number of basins in the Midwest, from Oklahoma all the way up to North Dakota, smaller Rockies basins and out into California and parts of Nevada.”

“That’s just thinking from a stable power generation standpoint. When we bring fluid cooling into the models, then more wells and more opportunities come forward. There are also similar geologic conditions in Canada, and in parts of South America and Africa.

“We see a really rosy future for sedimentary geothermal or oilfield geothermal, if you will. The repeatability across the world is quite strong.”

Low-temperature geothermal is also increasingly becoming more accessible with improving capabilities and lower prices of ORC units. Equipment costs have come down significantly in the last 10 or 15 years, providing more opportunities to harness geothermal resources at lower than 74 °C.

“It’s very exciting what the geothermal industry is doing with efforts to tap into ultradeep and ultra hot resources. That ecosystem of innovation is fantastic,” said Burke. “Low-temperature geothermal is the market niche that we have staked for ourselves, and we’re similarly excited about what we can do with this technology.”

According to Burke, it was a concerted business decision to focus on technologies that already exist and are already well-established. “We wanted to tell our investors that we are ready to go now. The technology is here now. This is not a science project. We can go out and generate electrons.”