Kurita Europe presenting geothermal solutions at EUROCORR 2021

At the virtual Eurocorr 2021 event, Kurita Europe will present corrosion and scaling inhibition studies for geothermal systems.

The European Corrision Congress Eurocorr 2021 is taking place as an online event September 20-24, 2021. The European Corrosion Congress (EUROCORR) is the flagship event of the European Federation of Corrosion (EFC) and is recognized as the corrosion congress with the highest academic level and industrial presence through scientific talks, poster presentations, and wide exhibition. It deals with a variety of subjects, including corrosion and scale inhibition; two of the most severe problems occurring when harvesting geothermal energy.

Kurita’s presence in EUROCORR is noteworthy, especially in the Workpackage -1 (WP1) Corrosion and Scale Inhibition session. In 2021 Kurita is participating in EUROCORR with six scientific presentations with collaborations of universities and institutes; on the subjects of corrosion, Antimony (III) Sulfide, and Aluminium Silicate, presenting corrosion and scaling inhibition studies for geothermal systems.

Kurita Europe presents the results of corrosion inhibition studies for geothermal systems.

Corrosion occurs due to a variety of dissolved chemical compounds included in a geothermal fluid, combined with high-temperature and high-pressure conditions that could accelerate the overall process. Carbon steel is widely used in industry due to its compatibility with other metals and its low cost. During the corrosion of steel, the formation of insoluble oxide particles takes place, the concentration of which is a powerful tool in the study of corrosion. We present the results of corrosion experiments based on different methods and various experimental conditions relevant to geothermal applications.

Significant scale inhibitor projects for specific deposition types seen in geothermal applications have been accomplished by laboratory tests and real-time field trials.

Three of our scientific presentations cover the full story of one of the most occurring scales in such systems: aluminium silicate; a persistent deposit whose structure, as it is formed in geothermal brines regarding the reservoir characteristics. This work starts with revealing the true nature of the so-called “aluminium silicate”, through a series of bench-top synthesis experiments under various conditions and complete physicochemical characterization. The research proceeds with developing the control strategies to be implemented for its mitigation starting from beaker tests and working our way up all the way (rephrase) to pilot plant and field trial tests.

One of Kurita’s state-of-the-art solutions can act as an effective dispersant of for Antimony (III) sulphide scaling. This type of deposition, although geographically limited, is especially observed in binary cycle geothermal power plants. Looking at the geothermal plants worldwide, antimony sulfide precipitation is mainly reported on the west coast of Turkey, in Italy, and New Zealand. Despite the widely conducted research on carbonate and silicate scaling, studies concerning the mitigation strategies towards antimony sulfide are limited. This contribution will present the effect of a new polymeric antiscalant as a successful antimony sulfide stabilizer, unchallenged by other existing treatments. Additional to the laboratory results, the superior efficiency of this product will be demonstrated with physical parameters observed during plant application.

Meet and connect with Kurita Europe at EUROCORR.

Click here to review the EUROCORR program and schedule.

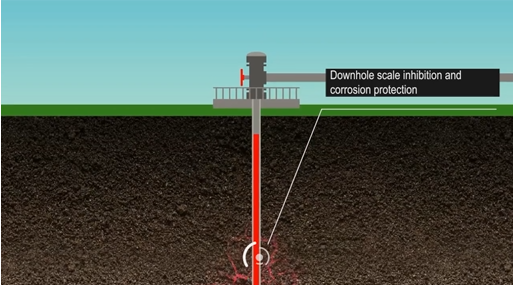

Kurita is the perfect partner to help the geothermal sites to improve their daily production and reduce the natural challenges of geothermal technology.

Kurita’s geothermal product range covers the treatment of different process zones, and it presents innovative solutions for production wells, pipelines, equipment, heat exchangers, cooling tower, and re-injection wells.

Don’t hesitate to contact the company’s experts in the field, we will be glad to search for the best customised solution for you.

Interested in learning more about Kurita? Read our article about “Kurita Europe’s new European technology center.