CATF publishes comprehensive study on superhot rock energy

The Clean Air Task Force has published a detailed report on the potential, initiatives, challenges of extracting geothermal energy from superhot rock systems.

The Clean Air Task Force (CATF) has published a report highlighting the potential of superhot rock energy as a form of advanced geothermal energy that is cost-competitive, sustainable, and available virtually anywhere on the Earth. The full report, titled “Superhot Rock Energy: A Vision for Firm, Global Zero-Carbon Energy” is available via this link.

Superhot rock systems and their benefits

Superhot rock energy refers to geothermal energy harnessed from deeper, hotter dry rock systems with temperatures of over 400 degrees Celsius. These systems can supply about five to ten times more energy per well compared to conventional hydrothermal systems. Moreover, being able to drill into superhot rock systems can make geothermal energy available nearly anywhere in the world.

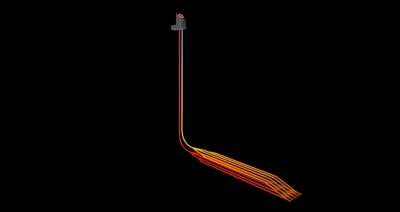

To harness the energy from superhot rock systems, water will be injected through deep injection wells which will then circulate through hard crystalline basement rock. The water will be heated within the subsurface fracture systems before it circulates back to the surface via production wells.

Superhot water is highly energy-dense because the water turns into “supercritical” fluid at very high temperatures and pressures. At this state, the fluid can penetrate through fractures faster because of low viscosities and high diffusivities. This allows for more energy to be brought to the surface through the production wells.

With its high energy potential, just a few superhot rock wells can supply enough geothermal energy for a commercially operating power plant. For instance, the Krafla borehole of the Iceland Deep Drilling Project (IDDP) has an estimated 36 MWe of energy production potential – up to 10 times higher than a typical hydrothermal geothermal well.

Superhot rock systems can also overcome the geographical limitations of developing geothermal power facilities only in regions where near-surface heat is available, such as in volcanic arcs or hotspots. Other benefits of superhot rock include reduced risk of drinking water contamination and smaller footprint of geothermal projects.

The economics of superhot rock projects

The CATF commissioned Hot Rock Energy Research Organization (HERO) and LucidCatalyst (LC) to estimate the levelized cost of electricity (LCOE) from superhot rock systems. A model was generated using Nth-of-a-kind costs and considering known wellfield and power generation costs from existing geothermal and thermal plants.

According to the model, superhot rock systems can produce electricity at a competitive LCOE of USD 20 -35 PER MWh. However, development costs are expected to be much higher for first-of-a-kind projects but will progressively decline through continuous improvement of technology and operational practices.

The economics of superhot rock projects can be improved by using them as a precursor for producing zero-carbon fuels such as hydrogen and ammonia. According to the model, hydrogen production costs using superhot rock energy can be below USD 1.50 / kg and can even reach USD 1/kg with advanced drilling and casing technologies. This is very competitive and will achieve the target cost of the 2030 Hydrogen Earthshot Initiative.

Existing superhot rock projects

Globally, there have been two dozen wells drilled into superhot rock conditions. These are generally located in areas with relatively shallow and high-temperature geothermal resources at depths between 3 to 7 kilometers. Power is yet to produced from these wells, but they have provided valuable information that has been instrumental in the progress of this initiative.

The aforementioned IDDP project is part of the EU’s DEEPEGS Program. The first well, IDDP-1 Krafla, was completed in 2009 but had to be terminated as it encountered magma. The second well, IDDP-1 Reykjanes, reached a temperature of 426 degrees Celsius in 2017. A third well is planned in Hengill near the Nesjavellir plant but is yet to be funded.

In Japan, a well drilled Kakonda back in 1994-1995 reached temperatures above 500 degrees Celsius at a depth of only 3.7 kilometers. Investigation revealed that the well was drilled into a brittle-ductile transition zone where the rock was less susceptible to brittle failure. The Japan Beyond Brittle Project (JBBP) continues at Tohoku University and is currently evaluating the drilling of a second exploration well.

GEMex, a Mexico-based EU program with focus on hot dry rock and super hot rock systems has drilled several wells at the Acoculco geothermal field with dry wells reportedly exceeding 300 degrees Celsius. There are plans of doing more drilling to investigate a super-hot resource near the Los Humeros geothermal field.

The Hotter and Deeper Exploration Science (HADES) project in New Zealand is actively exploring for superhot system in the Taupo Volcanic Zone and currently planning to drill a well into an inferred brittle-ductile transition zone at about 7 kilometers depth.

The DESCRAMBLE project in Larderello, Italy is another example of a successful completion of drilling into a superhot rock resource. The Venelle-2 well in Larderello is the hottest geothermal well on record with a temperature of 514 degrees Celsius at 2.9 kilometers depth. This project is also part of the EU DEEPEGS program.

Challenges to overcome for superhot rock energy

Aside from the challenge of locating superhot rock resources, new tools and technologies will also be needed to produce energy at superhot temperatures. The good news is that these are engineering challenges that do not need scientific breakthroughs.

Of particular interest are innovations in drilling technology that can make deep drilling faster and more economical. Particularly notable technologies are millimeter-wave drilling by Quaise, the PlasmaBit drilling technology by GA Drilling, and the particle drilling technology and hybrid polycrystalline diamond compact (PDC) bit by NOV and Particle Drilling Corporation.

Another challenge is to create reservoirs in dry superhot rock without causing seismic risks. This is something that can be addressed by the results of the Utah FORGE project. The closed-loop technologies of Eavor and GreenFire can also help in this regard by not relying on fracture systems for reservoir recharge.

Other critical challenges include well construction, developing sensors and electronics that can withstand superhot conditions, and adapting surface facilities to handle supercritical fluids. All these technologies have been anticipated for superhot commercial applications and are at various stages of development.

With drilling expertise needed for superhot rock projects, these provide a very good area for oil and gas professionals to pivot to renewable energy. Superhot rock projects can benefit greatly from the know-how of the oil and gas industry particularly in deep drilling, directional drilling, and planning of production wells for enhanced recovery or recharge.

Source: Clean Air Task Force