Ranging tools for geothermal – interview with Clinton Moss, Gunnar Energy Services

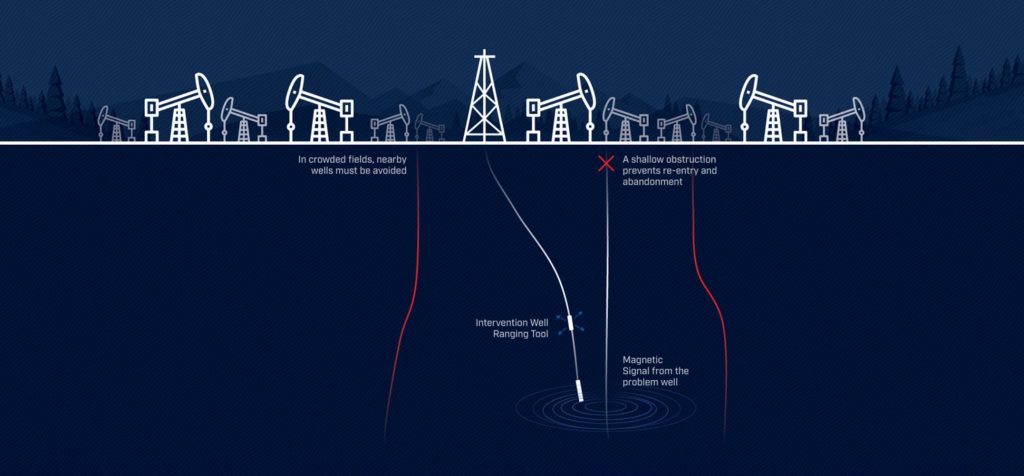

Magnetic ranging - a precise wellbore placement technology used to access particular zones of a geothermal heat reservoir or form closed-loops sees growing interest in the geothermal space says Clinton Moss of Gunnar Energy Services.

From time to time we stumble across rather interesting technical solutions and companies that deserve some specific coverage. In this case, we were connected with Clinton Moss, President of Gunnar Energy Services to learn more about the company’s work on magnetic ranging. For those not familiar with the technology it is a drilling technique to purposely direct drilling efforts in specific directions, e.g. purposely intersecting two wells to create a closed-loop geothermal system. So this is some extremely exciting stuff to come to geothermal, where hitting targets, and precision accuracy such as connecting wells etc become so important.

So we glad to get the chance to connect with Clinton.

For those of us that may be unfamiliar, please introduce yourself and Gunnar Energy Services

I started in the industry in 2005 working on drill rigs as a Measurement While Drilling Field Engineer, and in particular, utilized Magnetic Ranging tools from the very beginning. This ranged from Field Engineer, to Coordinator, Manager and finally Global Product line Champion for Magnetic Ranging services at Halliburton – Sperry Drilling. I briefly worked with Wild Well Control in Houston before starting my first business, Marksman Ranging Technologies. Marksman embarked on the rapid development of industry leading magnetic ranging technology, and subsequently commercialized and deployed these instruments at the wellsite within nine months of company inception. Marksman was acquired by Scientific Drilling International in 2015. As a part of that acquisition, the Marksman team continued as a wholly owned entity of SDI from 2015 to 2019. In 2019, I left Scientific Drilling International and started a new firm, Gunnar Energy Services. Gunnar is based in The Woodlands, Texas, with office and staff in the surrounding area.

Gunnar Energy Services is a firm dedicated to the development of technology and the provision of services in the complex completion, well intervention and well control segments of the energy sector. Gunnar is developing and deploying new technology to the field to address some of the industry’s most complex and challenging problems. Gunnar generally does not participate in large scale, factory drilling campaigns, but instead is laser focused on some of the energy industries most complex, unique and nuanced challenges. For example, Gunnar recently participated in the plug and abandonment of a well originally drilled in 1927, and partially abandoned in the 1950’s. Gunnar conceived of, develop, deployed and managed a new technology which allowed for the successful intersection and abandonment of that particular well in a timely and cost effective manner as compared to other commercially available solutions.

Would you walk us through the history of magnetic ranging and how the technology has evolved over time?

Magnetic ranging has been around for ~40 years or more in one form or another. The first magnetic ranging patents emerged in the late 1970’s and focused on determining a distance and direction from a drilled well to another nearby cased wellbore. This technique is often referred to as passive magnetic ranging. In the 80’s, active ranging was developed by Vector Magnetics. Vector Magnetics is considered the original inventors and suppliers of service of active magnetic ranging technology.

The technology was first developed to deal with taming oil well fires by way of “relief wells”. These techniques were later modified, or new related techniques developed, to allow for the precise placement of wellbores for oil and gas, construction, mining and geothermal applications.

What are a few of the common applications for ranging?

- If we want to purposely intersect two wells to create a closed loop geothermal system, magnetic ranging is deployed

- If we want to drill under a roadway and have a very precise exit point so that fiberoptic cables can be installed, we use magnetic ranging techniques

- If we want to purposely intersect a well so we can fill the old well with cement, thereby permanently abandoning the well, we use magnetic ranging

- If we want to drill wells so that potash (fertilizer) can be extracted by flooding the formation with fluid, thereby bringing the potash into liquid suspension, we deploy magnetic ranging

To further illustrate magnetic ranging applications and the complexity of these downhole conditions, I created an unscripted video series, entitled, “Pulling Back the Curtain” where myself and trusted industry colleagues walk through and explain complex well control, well intervention, and wellbore positioning challenges. Here is an example of one video, titled “Intro to Well Intervention” and you can watch the others on YouTube and shared on LinkedIn. We publish new videos weekly.

How do you see this technology making an impact in the Geothermal market and how will this differ from traditional O&G?

Magnetic ranging will make complex wellbore architecture possible in a geothermal application and has unlocked the full potential of deep and hot closed loop systems. It may well be the case that other complex completion geothermal drilling operations can be imagined, patented, and undertaken once magnetic ranging has been fully implemented as a tool in the geothermal drilling engineer’s toolbox. This is not unlike the oil and gas industry’s experience with magnetic ranging. Magnetic ranging made relief well drilling, steam assisted gravity drainage drilling and coal bed methane intersect drilling possible upon its introduction. Prior to the advent of magnetic ranging, these production or operational feats were not available to industry.

What new capabilities do you see this unlocking for Geothermal Operators and what risks will it present?

The precise placement of wellbores, whether it be to intersect and form a closed loop, or to precisely space multiple wellbores meant to access particular zone of the heat reservoir, will all be enabled by making magnetic ranging available in the geothermal drilling space.

The risks to these operations include the increase in engineering complexity as compared to a typical drilling operation (for example, drilling a deep vertical well). This risk can be well mitigated by seeding geothermal operations with O&G drilling engineers that are familiar and accustomed to designing and managing projects that routinely depend on magnetic ranging techniques.

With that said, the future of renewal energy must require a re-inventive mindset and consistently challenge the status quo. To generate more investment appeal into the Geothermal sector, we must much explore new methods for achieving our ultimate objectives – it is not about the outcomes, it is about the process and decisions that must fundamentally shift. What got us here won’t necessarily get us there.

—

We will check in with Clinton later this summer to dive further into some innovative magnetic ranging applications and concepts that should help advance the geothermal drilling industry and push the limits of development worldwide.