Innovative liner technology keeps corrosion at bay in geothermal wells

How can geothermal operators manage corrosion challenges in their wells? NOV’s proven TK-Liner system promises a reliable, cost-effective solution.

Natural gas is currently the main energy source heating the Netherlands’ buildings, greenhouses, and industrial infrastructure. The country is actively transitioning away from the use of natural gas and replacing it with sustainable energy sources including hot water that is produced from geothermal wells. By delivering sustainable heat, geothermal wells offer the promise of strengthening the economy and energy self-sufficiency of the country.

The geothermal market is not new in the Netherlands, but it’s facing significant challenges that may limit its long-term viability. Geothermal operators historically developed their wells on tight budgets using low-cost carbon steel for the well casing. But the typical operating environment of a significant proportion of these wells—water temperatures ranging from 85 degrees C to 95 degrees C, high salinity fluids, and the presence of oxygen—contributes to a highly corrosive environment for carbon steel.

Conventional solutions pose challenges

The oil and gas industry commonly combats corrosion in its carbon-steel tubing with chemical corrosion inhibitors. But recent resistance to using chemical corrosion inhibitors in the Netherlands curbs the long-term use of such chemicals in future geothermal applications.

Other potential solutions prove problematic. High-chrome corrosion-resistant alloys (CRAs) can withstand corrosive attack, but CRA pipe can be up to ten times the price of carbon-steel and difficult to source.

Some geothermal operators have considered glass-reinforced epoxy (GRE), mono-wall pipe. But given the well conditions, this pipe cannot provide sufficient structural integrity, particularly in the threaded areas.

A reliable, robust solution

Given the long payback periods for their wells, geothermal operators need smart well designs using cost-effective materials to ensure reliable, decades-long operation. In their search for non-chemical, non-CRA solutions for their corrosion challenges, operators in the Netherlands turned to NOV and its Tuboscope products for help. For more than 80 years, Tuboscope has provided excellent corrosion protection, hydraulic improvement, and deposit mitigation in tubular goods.

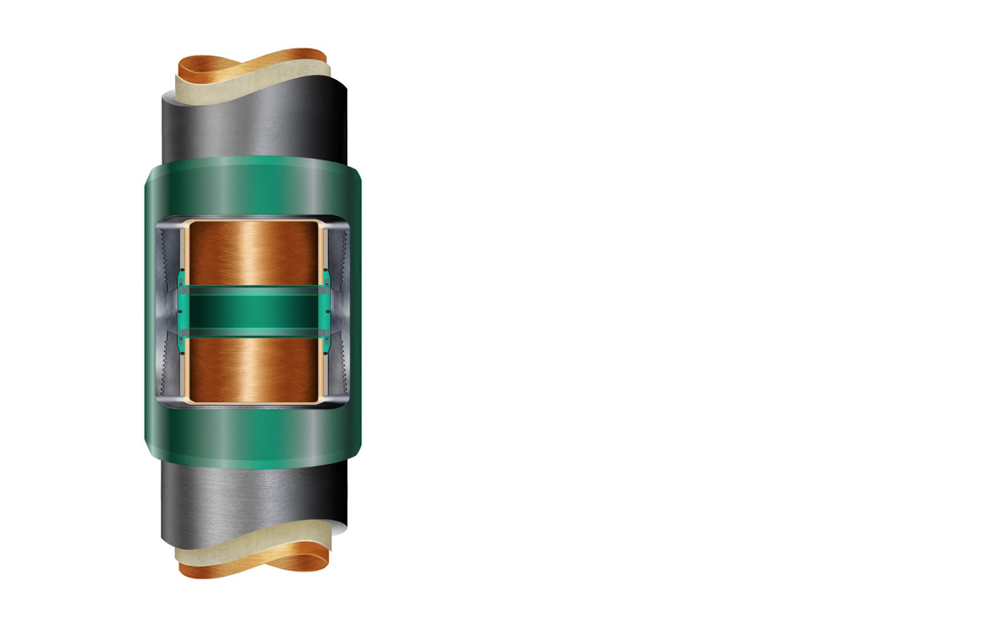

For the unique demands of geothermal wells, the Tuboscope TK (TM)-Liner technology delivers high-performance corrosion protection. TK-Liner products comprise a thin-walled GRE liner cemented inside a low-alloy carbon steel pipe. The liner delivers an effective corrosion and thermal insulation barrier while the carbon steel pipe reliably stands up to pressure and well loadings.

The technology’s corrosion protection extends to the threaded connections, thanks to the TK-Ring II system. Designed to fit any coupling system, the ring is installed into the joint between each pipe section and allows for the entire connection tolerance-range. The TK-Ring II technology is a mechanically-engaged concept that stands up to all well-induced stresses—ensuring a flush-transition, continuous gas-tight seal, corrosion protection and a prolonged life of the steel connections.

Proving its potential

More than 70 million feet of TK-Liner pipe are installed in high-temperature applications around the world. The largest diameter pipe previously lined was 10 ¾”, but for the Netherlands’ geothermal market, operators requested lined pipe up to 13-3/8” in diameter.

NOV embarked on further product development, including refining the pumping processes for Tuboscope’s standard raw materials and component designs. The company took special care to ensure that all components—including the TK-Ring II technology, liners, and connection-systems—would perform as required at the larger ID.

Full-scale pumping was conducted on customer “free issue” pipes. The full-diameter product, including the larger TK-Ring II product prototype, were assembled and installed without incident. One major Netherlands operator observed the installation testing and deemed the large-diameter TK-Liner product fit for service.

To date, Tuboscope has supplied many thousands of metres of TK-Liner systems for the Netherlands geothermal market, with sizes including 7 5/8”, 9 5/8”, 10 ¾” and 13 3/8”. The liner uses standard off-the-shelf base-pipe with un-modified premium connections, supported by Tuboscope and backed by the thread-proprietors’ licensee network.

“So far, nine wells have been successfully deployed into this exciting, emerging market,” says Tom McLaughlin with Tuboscope. “We are pleased to report that we have significant new contracts in place for 2022 projects in the Netherlands.”

For more information on NOV’s TK (TM)-Liner technology, visit https://www.nov.com/products/tk-liner.