Innovative packer and logging tools win US DOE Geothermal Manufacturing Prize

Two teams from Houston, Texas were selected as the winners of the US DOE's American-Made Geothermal Manufacturing Prize.

Two teams from Houston, Texas were selected as the winners of the Geothermal Manufacturing Prize by the U.S Department of Energy (DOE) Geothermal Technologies Office (GTO). Each winning team was awarded USD 500,000 in cash and up to USD 200,000 for field testing of their innovations.

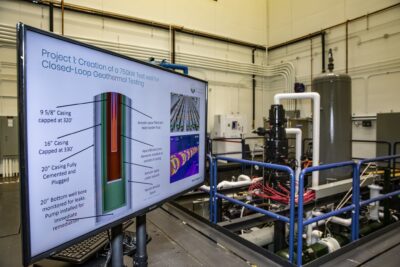

The American-Made Geothermal Manufacturing Prize is a $4.65-million competition that incentivize innovators to use 3D printing or additive manufacturing methods to address the challenges associated with operating sensitive equipment in harsh geothermal environments. Teams quickly developed, tested, and revised prototypes using additive manufacturing to support the advancement of geothermal tools and technologies. By focusing on manufacturing innovation, DOE is investing in improved performance, driving down costs, and expanding clean energy deployment.

During the course of the prize, which launched in January 2020, teams competed in three progressive competitions to propose a solution, design it, and create a prototype. The finalists presented their innovations at the annual Geothermal Rising conference in Reno, Nevada. The winning teams and their projects are as follows:

- Team Downhole Emerging Technologies (DET) developed an all-metal, retrievable packer system that is designed for the high temperatures, high pressures, and corrosive environments of geothermal wells. The partnership resulted in the largest Inconel additively manufactured components by Proto Labs Inc. and the development of the Diamond Extreme Temperature Isolation Packer (ETIP).

- Team Ultra-High Temperature Logging Tool developed a logging tool using a labyrinthian heat sink to reduce thermal emissivity and increase the exposure time of temperature-sensitive electronic components. Oak Ridge National Laboratory used a powder bed laser fusion technique to manufacture the heat sink design, with the aim that the technology would solve limitations around maximum temperature rating and lifetime of electronics in logging and measurement tools. The team also worked closely with Sandia National Laboratories to test the logging prototype in a high-temperature setting.

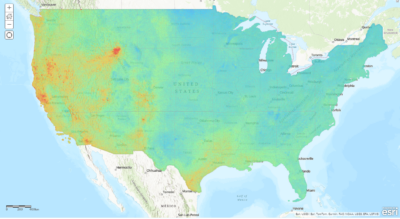

Harsh geothermal environments—high temperatures, nearly impenetrable rocks, and corrosive fluids—pose significant challenges for manufacturing tools, components, and equipment. These tools and equipment have high manufacturing costs because the small U.S. geothermal market results in low production volumes and harsh conditions shorten the lifespans of equipment.

Additive manufacturing can help improve the performance of geothermal tools and equipment by supporting the identification of high-performance materials, the creation of complex components, and quick development of prototypes, leading to rapid advances in geothermal manufacturing.

Source: US Department of Energy