Interview: Andrea Guglielmetti, Manager of geothermal drilling firm Petrevén Chile

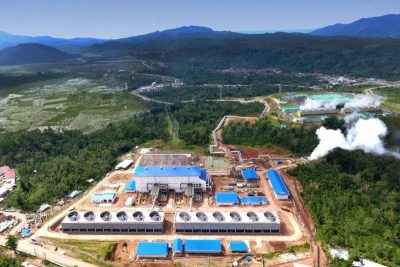

This is an Interview with Andrea Guglielmetti, Manager of Petrevén Chile, the company that drilled the wells for the geothermal power project of Cerro Pabellón, Chile.

In this interview with our Spanish geothermal news platform PiensaGeotermia, the drilling company Petrevén provides an insight into its drilling campaign for the Cerro Pabellón geothermal power project in Chile. Petrevén is an Italian company, with years of experience in the field of oil and gas drilling. The company currently operates 18 drilling and work over equipment in South America.

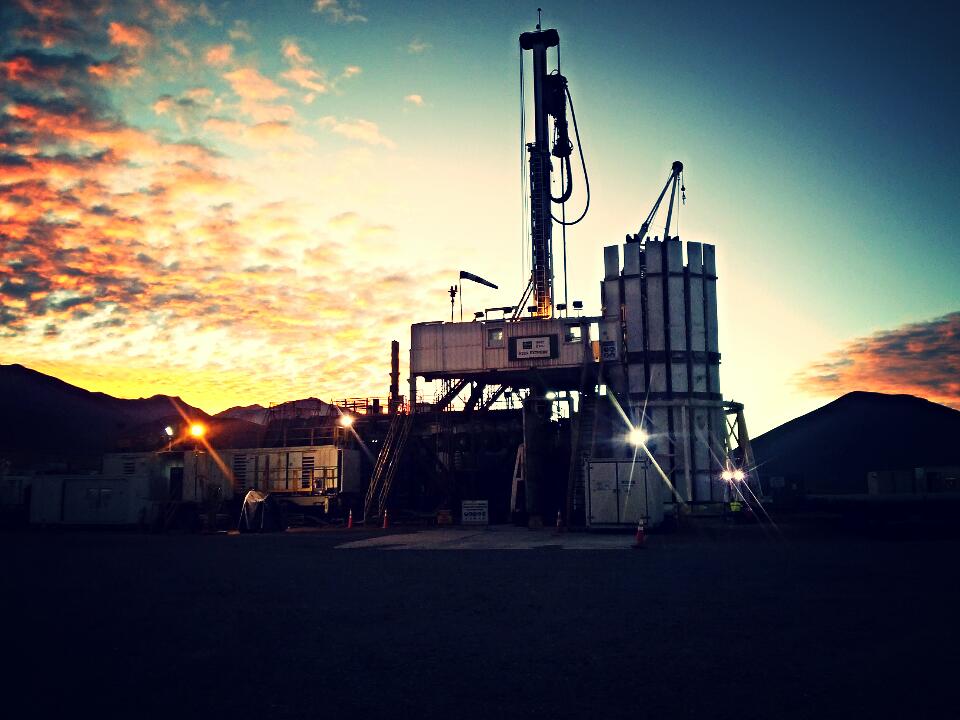

The equipment that Petreven has been operating on the Cerro Pabellón project site, is of the model DRILLMEC HH220 Extreme and specifically adapted to operate at the altitude of 4,500 meters. Drilling for the project began on November 01, 2015 and up to date, 7 wells have been drilled, equivalent to 13,500 meters of drilling.

In this interview, Andrea Guglielmetti, General Manager of Petrevén for Chile, tells us about his experience at Cerro Pabellón.

1. What are the characteristics of the location of this drilling campaign?

The project takes place at Cerro Pabellón (Atacama Desert, Antofagasta Region), at an average altitude of 4,500 meters above sea level, with a characteristic change of temperatures from -30 ° C in the winter season to + 18 ° C during the day. Due to these particular conditions, the H202 Extreme hydraulic equipment has been hydraulically modified and re-powered in generation, thus allowing the drilling without problems and complying with the profiles and standards of the geothermal wells.

2 . What have been the main challenges of drilling under these conditions?

Logistics in general was planned to compensate for the inconveniences related to the altitude and remoteness of the project. We also had inherent mishaps in materials and services specific to the activities, which are only linked to drilling (spare parts, tool inspections and supply of specific supplies of the item).

Due to the environmental conditions we had initial problems of adaptation and selection of the personnel involved, and as a company, Petreven, to improve the working conditions of its operators, has done a specific study on dealing with altitude sickness, where we were able to reduce the inherent problems of work in Height and not having hours lost due to health problems of the staff.

3. What are the additional security measures available to the equipment and the operation

The H202 Extreme has an integrated safety system, which allows to operate with a high safety standard, being for most of the automated and limited processes in manual activity of the technicians (automatic wedges, power tong, casing device, Automatic bar handling, state-of-the-art top drive with torque wrench).

All personnel involved have courses, trainings and training that minimize risk during operations. Petreven, having been certified to ISO 9.001 / 14.001 and OHSAS 18.001, has an annual activity development program that enables staff to remain active and to become aware of the risks of activities.

4. Regarding the original planning, how has the actual progress been?

The project had changes due to the good results of the wells drilled so far, we also comply according to the initial plan with the times defined in the program.

During the activities we had operational problems due to the complications of the wells such as legacy piping to the geology well and steam blow out that were solved with positive success.

The H202 Extreme team during the activity is meeting the expectations of the Client and did not present particular problems that could complicate or delay the operations and the times of the project, according to the contract KPI.

Inherent in the costs that had been budgeted initially, taking into consideration the environmental conditions,

5. Regarding the availability of the equipment, once Cerro Pabellón is finished, what can you tell us?

The team will be completing the Cerro Pabellón project, this year, and hope be able to keep the rig in Chile in the case of new geothermal projects. The equipment and the personnel of Petreven Chile, can adapt to all the environmental conditions presented by Chile in its geothermal fields, having demonstrated maximum efficiency and adaptability working in total safety.

In addition, this equipment is already conditioned to operate in any geothermal field throughout Chile or in any other part of the Andes of South America.

6. Regarding the offer of value to the geothermal developer, what can you tell us about working with Petrevén?

Petreven has consolidated experience in drilling since 1999, starting in Venezuela and actively present in Chile, Argentina, Peru, and Colombia.

The activities are carried out by a highly qualified personnel in the use of Drillmec hydraulic equipment, and Petreven can provide a complete service with the direct support of the manufacturer Drillmec in spare parts and technical assistance, if necessary.

The Investor of a geothermal project can count on Petreven to identify the most suitable drilling equipment for the drilling activities according to the environmental conditions and well design, and very important possibility to apply business models that can adapt to the requirement of the Client, Thus reducing costs in operations (O & M, Cost Plus, Daily Rate).

Petreven has an internal system for monitoring the performance of drilling rigs (KPI) and also with corporate preventive maintenance systems and integrated management system (GIS) platform, which allow to provide a high quality service with consequent focus On the achievement of objectives.

Andrea Guglielmetti’s contact details: email: aguglielmetti@petreven.com

Website: www.petreven.com

This interview was taken and shared on our sister publication, PiensaGeotermia.

Source: contact Petrevén via e-mail.